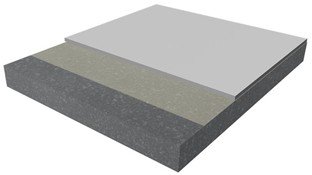

Strongcoat MD

Heavy duty solvent free coal tar modified epoxy based flooring system

Strongcoat MD is a heavy duty solvent free coal tar modified epoxy flooring system. Components of product composed of a base, hardener and graded filler, which when mixed form a fluid, homogenous slurry. After spreading Strongcoat MD slurry and while still wet, hard wearing silica aggregates should be broadcasted onto the slurry.

Strongcoat MD cures to a durable, anti-slip, extremely hard wearing surface. Depending on the used Antislip Aggregate, final dry thickness can be (2 - 2.5 mm) for normal traffic.

- Hard wearing system.

- Non-slip.

- Solvent free.

- Lightweight.

- Fast cure.

- Waterproof.

- Flexible.

- Resists a wide range of chemicals, consult DCP technical department for more details.

Strongcoat MD is used to provide a hard wearing anti-skid surface for concrete and steel floors for a wide range of applications such as:

- Car parks.

- Roads and bridges.

- Off shore oil platforms.

- Ship decks.

- Industrial floors.

- Helicopter decks (pad).

Strongcoat MD: 4.36 kg/m² @ 2.5 mm thickness.

Strongcoat Primer: 5 m²/kg @ 200 microns DFT.

Silica Aggregates: 5 - 6 kg/m² using Antislip Aggregate #2, and 6.5 - 7.5 kg/m² using Antislip Aggregate #0.

Strongcoat MD is available in 30 kg packs.

Strongcoat Primer is available in 5 kg packs.

Silica Aggregates is available in 25 kg bags.

Strongcoat MD and Primer have a shelf life of 12 months from date of manufacture if stored at temperatures between 5°C and 40°C.

- Strongcoat MD complies with EN 13813, SR-B2.0-AR0.5-IR10.