Bitumen Based Waterproofing / Cold Applied

Tools and Equipment

Surface Preparation

- All surfaces to be waterproofed must be clean, sound, dry and free of all surface contaminations such as form release agents, curing compounds, laitance, dust, dirt, cavities, projecting nibs, etc. laitance should be removed from concrete by grit blasting or wire brushing.

- Ensure the substrate surface is dry, smooth, and any surface imperfections repaired with a suitable cementitious repair mortar.

Application

- Mix materials well before use.

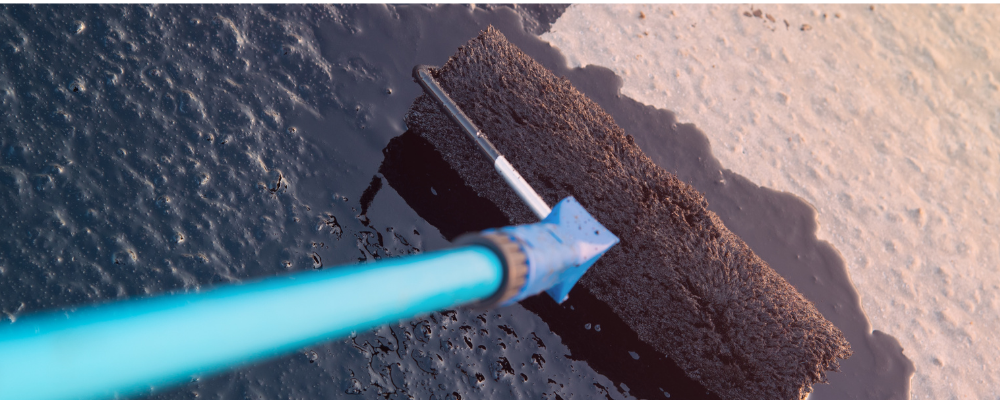

- Using a suitable brush or roller, apply first coat

- While first coat is still wet, all right angle corners and pipes/drain penetrations shall be reinforced with 20 cm wide fibre glass mesh (60 g/m2 or more) and allowed to dry.

- Apply second coats at right angle to the first coat and allow to dry.

Recommendations

- Unmixed materials and equipment should be stored in cool place and away from direct sunlight.

- Plan for enough material, tools and labors to avoid any stoppage during the application process.

- Avoid application through peak temperatures of the day.

- Ensure proper and adequate ventilation.

DCP Bitumen Based Waterproofing

Bituproof 320 :Water based elastomeric high build latex rubberised bitumen coating.

Bituproof FLX :Water based elastomeric rubberized bitumen waterproof coating.

Bituproof 50R :Water based latex rubberised bitumen protective coating

Bituproof 40S :Water based bitumen coating