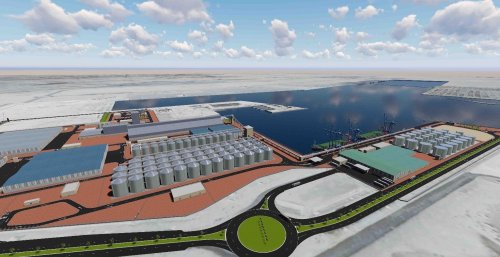

Kattupalli Port Project

Task at Hand

This would-be-largest shipyard project in Asia was demanding high performance for its concrete mixtures. The venture required a 50% slag product as an admixture to ensure higher quality of the concrete mixture in its fineness, air permeability and activity index, and compressive strength.

Compatible Sodium Naphthalene Sulfonate Formaldehyde Condensate (SNF) admixture should be added for slag to demonstrate higher criteria such as higher slump control and retention time for 1 hour and compressive and flexural strength. Concrete strength grades ranging from M10 to M45 were designed for various structures. Giant cement blocks (Accropodes) were proposed to be of M30 strength grade. In the process of casting these elements, bleeding and any surface blemishes should be completely eliminated.

DCP SOLUTION

There were two main challenges: the Accropodes with high flowability concrete and the SNF admixture. Based on mock-up studies and research, we arrived at an excellent tailor-made SNF product design. Initial observations showed that bleeding was highly minimised. Below is a detailed description of the final mix design:

Final Mix Design

- Cement - 230 kg/m³

- GGBS - 160 kg/m³

- Free water - 165 litres

- 100% crushed sand

Surface finish met the high criteria requirement and the desired strength was achieved.

For more information on the case study, download the attached file. You can find it right under "Project Info". Follow us on social media for more interesting case studies!